1. Sourcing the Raw Material

Every masterpiece starts with raw magic. Wool is sourced from the high deserts of Bikaner, where the prized Chokla wool is auctioned twice a year. This isn’t just any wool—it’s fleece with character, sorted by hand using generational knowledge. We also import buttery-soft Merino wool from New Zealand, and blend fibers from 18+ countries to get the perfect cocktail of softness, sheen, and strength. Add to that the quiet luxury of Chinese silk, and the foundation is set.

2. Sorting & Cleaning

The raw wool arrives unfiltered, rough around the edges—much like talent in its rawest form. It’s hand-sorted by texture, length, and colour, then thoroughly washed to remove dust, oils, and impurities. Only the best makes the cut.

3. Carding & Spinning

Enter the Katwari—the unsung spinner. She layers the wool, combs it gently, and teases out a rhythm using two bristled pads, aligning fibers into soft, uniform waves. Then, with her charkha (spinning wheel), she conjures yarn from air and intuition. It’s a soulful, meditative process. What she creates isn’t just thread—it’s resilience spun into beauty.

4. Dyeing

Next, the yarn meets colour. Not in a hurry, but in boiling cauldrons of custom-mixed, eco-certified dyes. We work with over 3000 colours, creating unique shades like chefs creating secret sauces. The yarn is then sun-dried, developing natural variations called Abrash—a mark of authenticity, and a reminder that no two handmade things are ever truly the same.

5. Design & Mapping

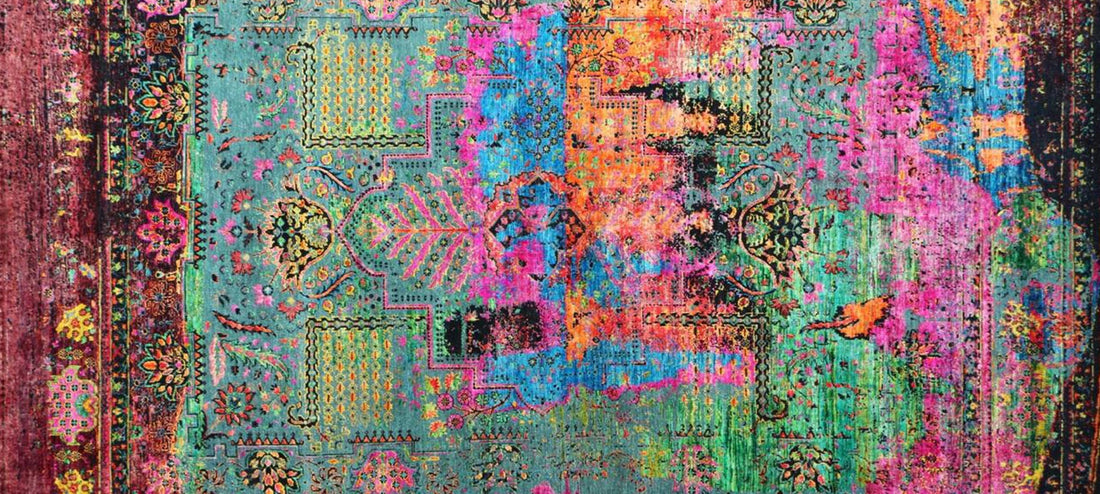

Before a single knot is tied, the rug must be imagined. Artists hand-sketch motifs or use nakshas (colour-coded graphs), mapping out every curve, border, and bloom. Whether traditional Persian florals or bold, modern geometry—this is the blueprint for brilliance.

6. Weaving

Now comes the real flex. On a loom, the weaver begins tying individual knots—hundreds of thousands of them. Each knot is a decision. Each row, a quiet act of devotion. Depending on the technique—hand-knotted, hand-tufted, flat-weave, or handloom—the process can take anywhere from weeks to months. This is where the rug finds its soul.

7. Trimming & Washing

Once woven, the rug is trimmed by hand to achieve the perfect pile height and clarity of design. Then it’s washed—often multiple times—to soften the fibers and bring out the lustre. Think of it as a final rinse before the runway.

8. Stretching & Finishing

The rug is now stretched on a frame to ensure the edges are perfectly aligned. Final touches include edge binding, fringing, or back-finishing. Every detail is checked, double-checked, and loved into place.

9. Inspection & Quality Check

Before it ever touches a floor, each rug goes through rigorous quality control. We inspect for consistency in weave, colour, size, texture, and overall swag. If something feels even slightly off—it doesn’t go out.

10. Packing & Shipping

Finally, the rug is packed with care, often with a handwritten note or story tag, and shipped across the world—ready to live its best life in someone’s home, sparking compliments and quiet envy wherever it lands.

From sheep to chic, a rug’s journey is one of patience, passion, and precision. It's a 180-hand relay of heritage and hustle—where every twist of yarn carries the soul of the maker, and every knot is tied with quiet, confident swag.